Processing and customized Silicon carbide ring/axle sleeve

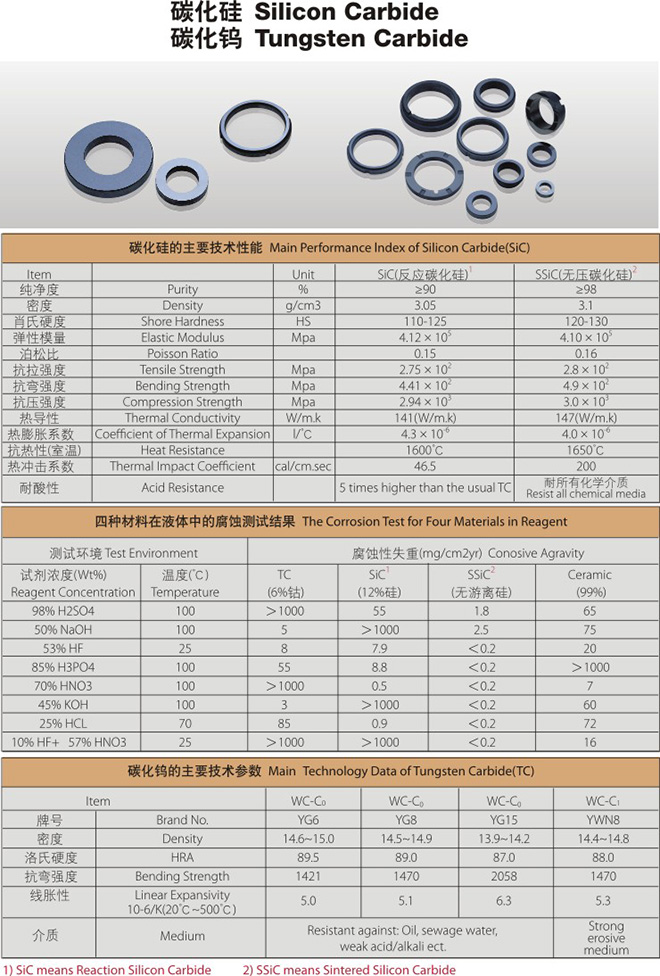

Silicon carbide belongs to the engineering ceramics which has good chemical stability, and suits to the mediums with strong corrosivity. It has high conductivity coefficient and low dilatation coefficient and under high temperature, the inconsistency of performance change little. Silicon carbide loop/axle sleeve was produced by processing the submicron order SiC powder, by using the way of reaction or pressureless sintering. It is the compact SiC ceramic product. It does not contain the free silicon and the tiny grains are tiny. It has the good properties, such as high temperature resistance, high strength, high hardness, good corrosion resistance and oxidation resistance.

At present, it is the preferred and common material for the developed countries to produce the machine sealing rings, blast nozzles, bulletproof sheets, magnetic drive pumps and the parts of shield pump and especially suits to the corrosive mediums which conveys the strong acid and strong base and so on. So it was widely used in the all kinds of industrial fields, such as petrochemical engineering, electric power, light industry, aerospace, automobile, papermaking and sewage treatment. Combining with the carbon graphite, they have the smallest friction coefficient, so they can be used for producing the high-end mechanical seal parts.

SEALOK can designed and developed the products which suit to the customers, according to their requirements and Working condition,and Sealok also can produce the products for the customers, according to their drawings or sample plates.